Product description:

The PIR (Polyisocyanurate) panels are better quality than PUR (Polyurethane) panels. PIR panels is a new generation with better quality. Such as longer service life, better foaming, higher fire proof performance and longer sizes, etc. It’s becoming popular, especially for those huge cold room projects.

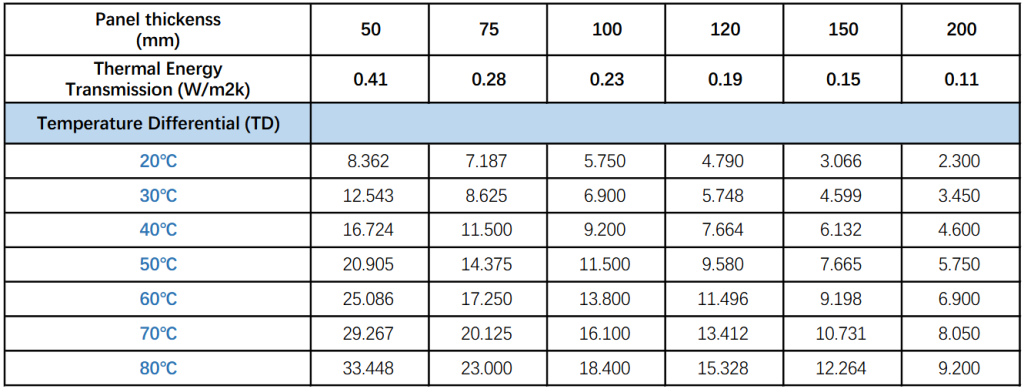

1# Thermal energy transmission (W/m2K):

It’s based on different temperature difference (TD). Usually 100mm PIR panels for chiller room or processing room, and 150mm for freezer room, and 200mm panels are for blast freezer or deep freezer.

2-1# Density of the foaming

As we know, the best density is 40~42kg/m3. But some suppliers may use low density foaming to lower their production cost. In our factory, you don’t need to worry this. We know how to lower the quality, but we never do that. As consumers like you, you could do a quick test just like below steps:

Hard to push your fingers into the foaming. High density.

Easy to bury your fingers into the foaming. Low density.

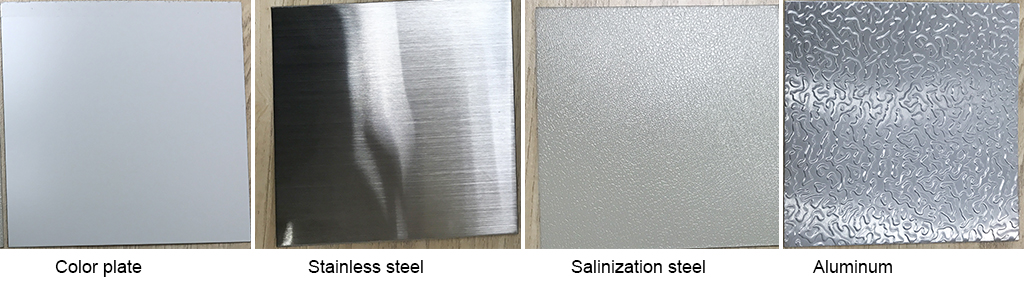

2-2# Steel on two sides

The color plate is more popular for these PIR panels. Usually we’ll use 0.5mm thickness, BAOSTEEL brand, with polyester paint, and 120 g/m2 zinc-coated layer. But some supplier may only use 0.426mm thickness and 30 g/m2 zinc-coated layer, which quality is not so good.

2-3# A good fireproof could save life in some extreme cases:

B1 grade PIR foaming is better than the B2 grade. Look at below pictures and pay attention to the burning and smoke. It’s easy to do such test.

4# More details:

High density PIR foaming and best brand BAOSTEEL color plate.

5# Our factory in Shanghai, China:

All these years, we’re focusing on the high quality market, so we try best to produce the quality products, and build the modern production lines, standardized quality control standards, and professional engineers teams, and sales teams, etc.

6# Some cold room projects:

Many projects have been done in different countries in past years, and more would be done in future. If you would like to see whether there are some projects near you, just contact our sales department, and we’ll share to you.

These countries include: United States, Mexico, Panama, Ecuador, Peru, Chile, Guyana, Uruguay, and other countries, etc.

7# Let’s visit and talk:

Our sales teams would visit clients each year, besides provide the after sale service, we would also need to check out how our refrigeration equipment have been working and how to improve.

If you have a project, visit us in China, or invite us and we’ll visit. Talking face to face, could confirm details in short time, and build the trust with each others.

8# FAQ (Frequently asked questions)

- Where is our factories? They’re near Shanghai, China.

- How long is the production time? 10~15 days.

- Where is our sea port? Shanghai port, China.

- How about the warranty and guarantee? Warranty 1 year, and guarantee all are brand new components.

- How about installation? You need a local team, and we’ll give manual, drawing and diagram, etc. If necessary, we’ll send our engineers on site.

- How about the payment terms: T/T, L/C or Alibaba trade assurance, etc.

- What’s the brand of the refrigeration equipment: Compressor would be German Bitzer, and key components are Siemens, Schneider, Danfoss and Emerson, etc. Whole equipment is our own brand Nuo Nuo.